If you need any help, please feel free to contact us

Fading Issues In Transfer Printing And How To Reduce Them

Transfer printing has become a widely used method in customizing textiles, promotional items, and various other products. However, one common challenge faced by manufacturers and hobbyists alike is the fading of prints over time. Fading not only affects the visual appeal of the printed item but can also impact customer satisfaction and the perceived quality of the product. This article explores the causes of fading in transfer printing and offers practical solutions to reduce this issue, with particular attention to the role of printing materials such as lightweight glossy photo paper, 200 gsm glossy photo paper, and 180 gsm glossy photo paper.

Understanding Fading in Transfer Printing

Fading occurs when the colors in a transfer print gradually lose their intensity due to exposure to factors like sunlight, washing, heat, and abrasion. The dyes or pigments used in the inks can break down or migrate from the surface, causing dullness and discoloration. Environmental conditions such as UV radiation and moisture accelerate this degradation process, making it a crucial consideration for anyone involved in transfer printing.

Factors Contributing to Fading

Several factors influence how quickly and severely fading occurs in transfer printing:

Ink Quality and Type: Different inks have varying resistance to fading. Dye-based inks, while vibrant, tend to fade faster under UV light compared to pigment-based inks.

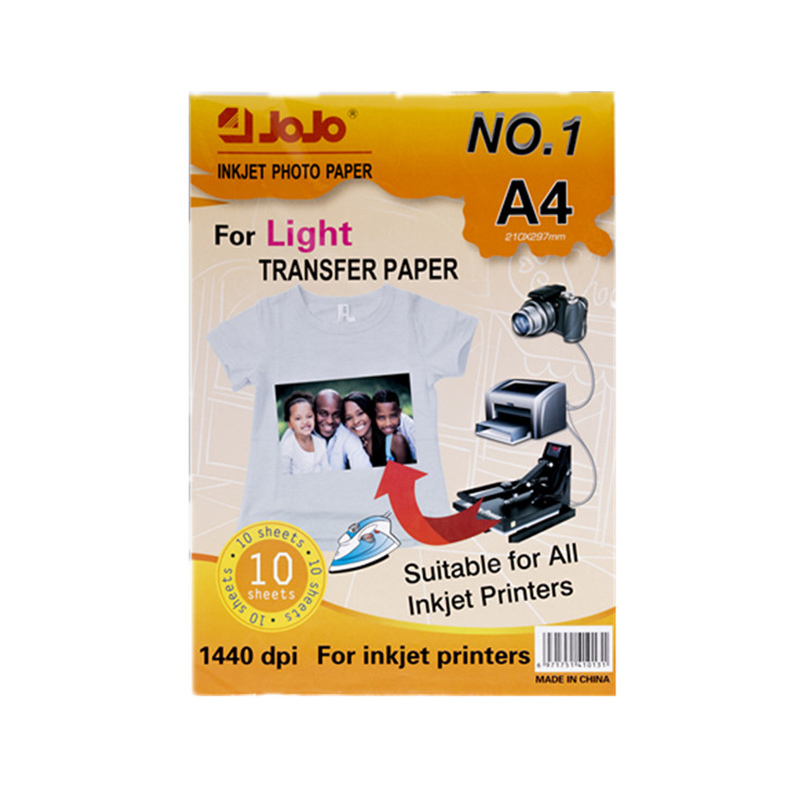

Transfer Paper Quality: The choice of transfer paper significantly impacts the durability of the print. Papers designed specifically for heat transfer printing tend to bond better with inks and substrates.

Fabric Type: The type of fabric receiving the transfer plays a role. Synthetic fibers like polyester usually hold dye sublimation prints better than natural fibers such as cotton.

Heat and Pressure Settings: Incorrect heat or pressure during the transfer process can advance to incomplete ink adhesion, which results in early fading.

Role of Photo Paper in Transfer Printing

While transfer printing primarily involves specialized transfer papers, photo papers such as lightweight glossy photo paper, 200 gsm glossy photo paper, and 180 gsm glossy photo paper can also be part of the process in certain digital print applications or prototypes.

Lightweight Glossy Photo Paper: This type of paper is thinner and flexible, allowing easier heat transfer. However, its lightweight nature may limit the amount of ink it can hold, potentially affecting the print’s durability.

200 gsm Glossy Photo Paper: This medium-weight photo paper provides a balance between thickness and flexibility. It can hold more ink, offering richer colors and slightly better resistance to fading when used appropriately in printing processes.

180 gsm Glossy Photo Paper: Slightly lighter than the 200 gsm variant, this paper offers good surface smoothness and gloss, which helps in achieving sharp and vivid prints. However, the difference in weight affects ink absorption and print longevity.

When considering photo papers for transfer printing or related applications, it is important to assess their coating and compatibility with transfer inks and methods. Coated photo papers generally help in ink fixation, which can indirectly reduce fading.

Strategies to Reduce Fading in Transfer Printing

Select High-Quality Transfer Papers and Inks

Choosing transfer papers engineered for heat transfer processes and inks with strong pigment properties improves the durability of prints. Papers that bond well to fabrics and retain color pigments tend to resist fading longer.

Optimize Heat Press Settings

Following the recommended temperature, pressure, and time guidelines ensures proper ink adhesion. Overheating or underheating can weaken the print’s resistance to washing and UV exposure.

Use Protective Coatings

Applying clear protective films or sprays designed for transfer prints adds a barrier against abrasion and UV rays. These coatings can be particularly effective for items exposed to frequent washing or sunlight.

Pre-Treat Fabrics When Necessary

For natural fabrics like cotton, pre-treatments improve ink bonding. Pre-treatment solutions designed for transfer printing can enhance colorfastness and reduce fading.

Wash and Care Instructions

Educating end-users on proper care extends the life of transfer prints. Washing inside out with mild detergents, avoiding bleach, and air drying rather than tumble drying helps maintain color integrity.

Testing and Quality Control

Conducting tests on small batches using different photo papers, such as lightweight glossy photo paper, 200 gsm glossy photo paper, and 180 gsm glossy photo paper, can help determine which materials yield better fade resistance under specific conditions.

Fading is an inherent challenge in transfer printing, but it can be significantly mitigated by understanding its causes and adopting appropriate materials and techniques. The choice of paper, including options like lightweight glossy photo paper, 200 gsm glossy photo paper, and 180 gsm glossy photo paper, plays a role in how well the inks adhere and withstand wear. By optimizing transfer processes and using protective measures, manufacturers can deliver prints that maintain their vibrancy and meet customer expectations over time.

English

English Español

Español 中文简体

中文简体 Português

Português