If you need any help, please feel free to contact us

Introduction To Sublimation And Heat Transfer Paper

Sublimation and heat transfer printing have become popular methods for producing vibrant, durable images on various substrates, including textiles, ceramics, and promotional products. Both techniques rely on specialized transfer papers to ensure quality results, but their properties and applications differ significantly. Understanding these differences is crucial for selecting the right media to meet specific printing needs.

What is Sublimation Printing?

Sublimation printing is a digital printing process that uses heat to transfer dye onto materials such as polyester fabric, coated metals, or plastics. The key feature of sublimation is that the dye turns from a solid into a gas without passing through a liquid stage—a process called sublimation—allowing the dye to penetrate the surface of the substrate. This results in images that are embedded into the material rather than sitting on top, producing durable and vibrant prints.

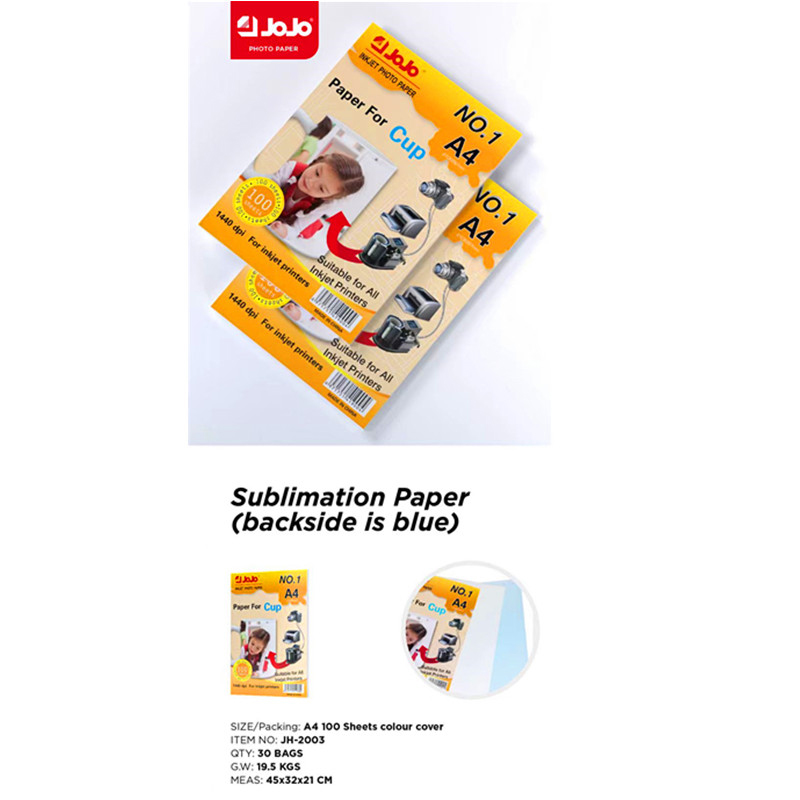

Sublimation paper plays an important role in this process. It is specially coated to hold and release sublimation dye efficiently during heat transfer. Quality sublimation paper ensures sharp images with consistent color reproduction and small ink bleed. The paper must also withstand high temperatures and pressures without warping or degrading.

What is Heat Transfer Printing?

Heat transfer printing is a broader category that includes several printing techniques where an image is printed onto a transfer paper and then transferred onto a substrate with heat and pressure. Unlike sublimation, the ink or toner stays on the surface and is adhered to the substrate using adhesives or melting layers. Heat transfer is widely used for printing on cotton, blends, and other fabrics that cannot accept sublimation dyes.

Heat transfer papers come in various types, including ones designed for light or dark fabrics, and those compatible with inkjet or laser printers. The choice of paper affects print quality, durability, and feel of the final product. Heat transfer papers typically require precise control of temperature and pressure during the transfer process to ensure proper adhesion and avoid issues such as cracking or peeling.

Differences Between Sublimation and Heat Transfer Paper

The main difference between sublimation and heat transfer paper lies in the printing mechanism and compatible substrates. Sublimation paper releases dye that bonds at a molecular level with polyester or coated surfaces. Heat transfer paper, on the other hand, carries pigments or toner that must adhere to the substrate's surface using adhesives or heat-activated layers.

When choosing paper, users must consider factors like the printer type, substrate material, and intended application. Sublimation papers require printers that support sublimation inks, whereas heat transfer papers can work with standard inkjet or laser printers, depending on the product.

Specialty Photo Papers in Digital Printing

Beyond transfer papers, specialty photo papers like satin inkjet photo paper, smooth photo paper, and pearl photo paper serve unique purposes in digital imaging and printing.

Satin Inkjet Photo Paper offers a semi-gloss finish that balances vivid color reproduction with moderate reflectivity. This paper type is favored for portrait prints and photo books, where a subtle sheen enhances image depth without harsh glare.

Smooth Photo Paper features a flat, even surface that allows ink to sit uniformly, resulting in sharp details and consistent colors. Its texture makes it suitable for fine art prints, graphic designs, and photographs where clarity is critical.

Pearl Photo Paper has a slightly textured finish that resembles a pearl or metallic sheen. This effect adds a touch of elegance and dimension to prints, making it a popular choice for wedding photos, event portraits, and high-end promotional materials.

These papers, while not specifically designed for sublimation or heat transfer, demonstrate the variety of options available to photographers and print professionals. Each finish impacts the appearance and feel of the printed image, offering creative flexibility.

Choosing the Right Paper for Your Project

Selecting the appropriate paper depends on the printer, substrate, and desired output characteristics. For sublimation printing on polyester fabrics or coated surfaces, dedicated sublimation transfer paper is essential to ensure accurate color transfer and longevity.

For heat transfer printing on cotton or mixed fabrics, compatible heat transfer paper designed for the printer type and fabric color will provide better adhesion and durability. Testing is often necessary to optimize transfer settings and avoid issues like fading or peeling.

When printing photographs or art prints with an inkjet printer, satin inkjet photo paper, smooth photo paper, and pearl photo paper offer a range of finishes to suit various aesthetic preferences. These papers enhance the image quality and presentation without additional processing steps.

Sublimation and heat transfer printing each provide distinct advantages for producing high-quality prints on different substrates. Understanding the role and characteristics of sublimation and heat transfer papers helps printers achieve consistent results tailored to their applications. Meanwhile, specialty photo papers such as satin inkjet photo paper, smooth photo paper, and pearl photo paper continue to support creative expression in digital photography and printing.

Choosing the right paper is a key step in any printing workflow, influencing the final product's appearance, durability, and feel. Whether working with heat transfer, sublimation, or photo printing, selecting materials that match the printer and project requirements will contribute to successful outcomes.

English

English Español

Español 中文简体

中文简体 Português

Português