If you need any help, please feel free to contact us

Ink Consumption: Factors That Influence Efficiency

Ink consumption is a critical consideration in digital printing, impacting both the cost and quality of printed materials. For businesses and individuals using inkjet printers, understanding the factors that affect how much ink is used can help optimize printing processes and reduce waste. This article explores key elements that influence ink efficiency, with particular attention to media types such as A4 size glossy photo paper, thick thermal paper, and thermal paper 57mm, which are commonly used in various printing applications.

The Role of Printing Media in Ink Consumption

One of the main factors influencing ink consumption is the type of printing media. Different papers absorb and interact with ink in distinct ways, affecting the amount needed for satisfactory image quality.

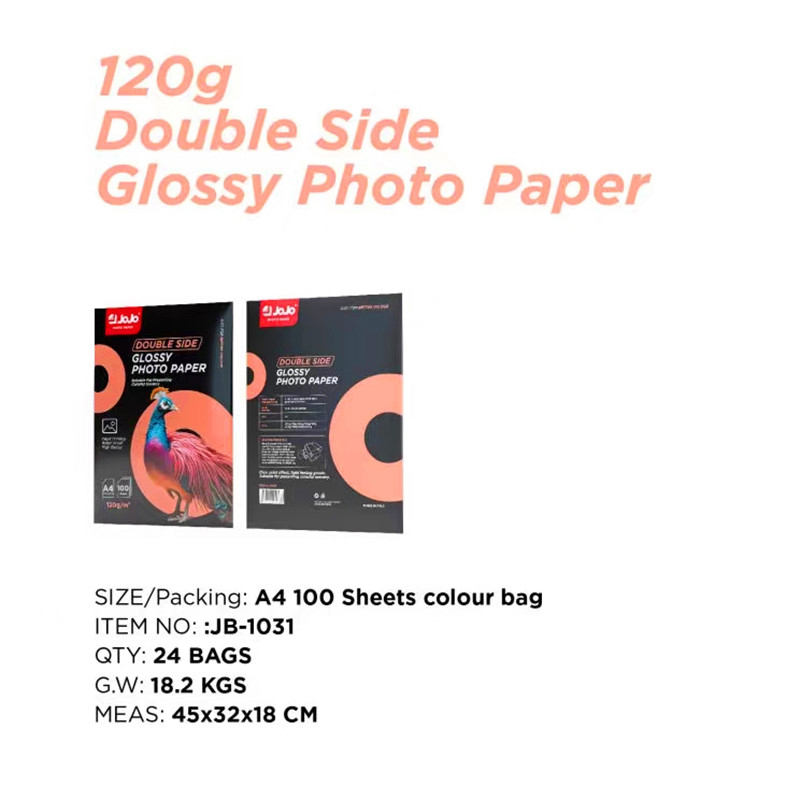

A4 size glossy photo paper is a popular choice for high-quality photographs and presentations. Its smooth, coated surface allows ink to sit on top rather than being absorbed, which can advance to vibrant, sharp prints. However, glossy papers often require more ink compared to matte papers because the ink droplets remain visible on the surface, demanding precise coverage to avoid streaking or patchiness. The coated surface also tends to dry more slowly, which can affect how the ink spreads, further influencing consumption.

On the other hand, thick thermal paper is often used in receipt printing and other specialized applications. Unlike photo papers, thermal paper is coated with a heat-sensitive layer that reacts to thermal print heads rather than liquid ink. Although thermal printing uses different technology, if thermal paper is used in combination with ink-based printers for labels or tags, its thickness and surface properties can affect ink absorption and drying time. Thicker papers generally require more ink because the surface may have a texture or coating that demands heavier ink application for clear visibility.

Similarly, thermal paper 57mm is a narrower roll commonly used in point-of-sale (POS) systems and small-format printing devices. Like thick thermal paper, the width and coating influence printing dynamics, but the reduced size can sometimes advance to less ink consumption per page simply due to the smaller print area. However, the coating quality and paper finish still affect how much ink is necessary to produce legible and durable prints.

Printer Settings and Ink Efficiency

Apart from the media, printer settings play a crucial role in ink consumption. Factors such as print resolution, ink droplet size, and print mode (draft, standard, or high-quality) directly affect how much ink is used.

Higher print resolutions require more ink because the printer deposits finer dots closer together to produce detailed images. When printing on A4 size glossy photo paper, selecting a high-resolution mode can enhance the output's visual quality but will increase ink use. Conversely, draft modes use less ink but can result in grainy or faded prints, which may be unsuitable for professional presentations.

For thick thermal paper and thermal paper 57mm, printers designed for these materials typically use thermal transfer or direct thermal printing methods that don't rely on ink. However, if inkjet or laser printers are used on thermal paper for special projects, adjustments to the print mode are necessary to balance ink use and print clarity.

Ink Formulation and Quality

The formulation of the ink itself influences consumption and efficiency. Pigment-based inks, which contain solid particles suspended in liquid, tend to be more resistant to fading and water damage but may require larger amounts to achieve desired opacity. Dye-based inks, which dissolve in liquid, usually produce brighter colors with less ink but can be less durable.

When printing on A4 size glossy photo paper, pigment inks often provide better longevity, but the increased volume needed can impact overall ink use. For applications involving thermal papers, the type of ink is less relevant for traditional thermal printing but important when hybrid printing methods are applied.

Environmental Conditions and Paper Handling

Environmental factors such as humidity and temperature can affect how ink behaves on paper surfaces. High humidity levels may cause ink to spread or bleed more on glossy photo paper, requiring more ink for coverage to maintain image quality. Similarly, thermal papers exposed to heat or moisture may react prematurely or degrade, impacting print quality and necessitating repeat prints that increase ink consumption.

Proper paper handling and storage are essential to maintain the integrity of A4 size glossy photo paper, thick thermal paper, and thermal paper 57mm. Keeping media in controlled environments reduces the risk of curling, moisture absorption, and surface damage that could affect printing efficiency.

Print Design and Coverage

The amount of ink used also depends on the design and coverage area of the print job. Images with large solid areas, dark backgrounds, or saturated colors consume more ink than documents with light text or sparse graphics. When using A4 size glossy photo paper, designs with extensive photographic content or heavy color blocks naturally require more ink.

In thermal paper printing, particularly with 57mm rolls used in receipts or tickets, the print design is usually small, focusing on text and barcodes, which keeps ink use relatively low. However, when thermal papers are adapted for graphic-heavy printing via ink-based methods, the design density becomes a significant factor.

Ink consumption is influenced by a combination of media type, printer settings, ink formulation, environmental conditions, and print design. Understanding how these factors interact, especially with media like A4 size glossy photo paper, thick thermal paper, and thermal paper 57mm, helps users manage costs and improve printing efficiency. By selecting appropriate media, adjusting printer settings, and optimizing designs, businesses and individuals can better control ink usage without compromising print quality.

English

English Español

Español 中文简体

中文简体 Português

Português