If you need any help, please feel free to contact us

How Ink Composition Affects Color Accuracy

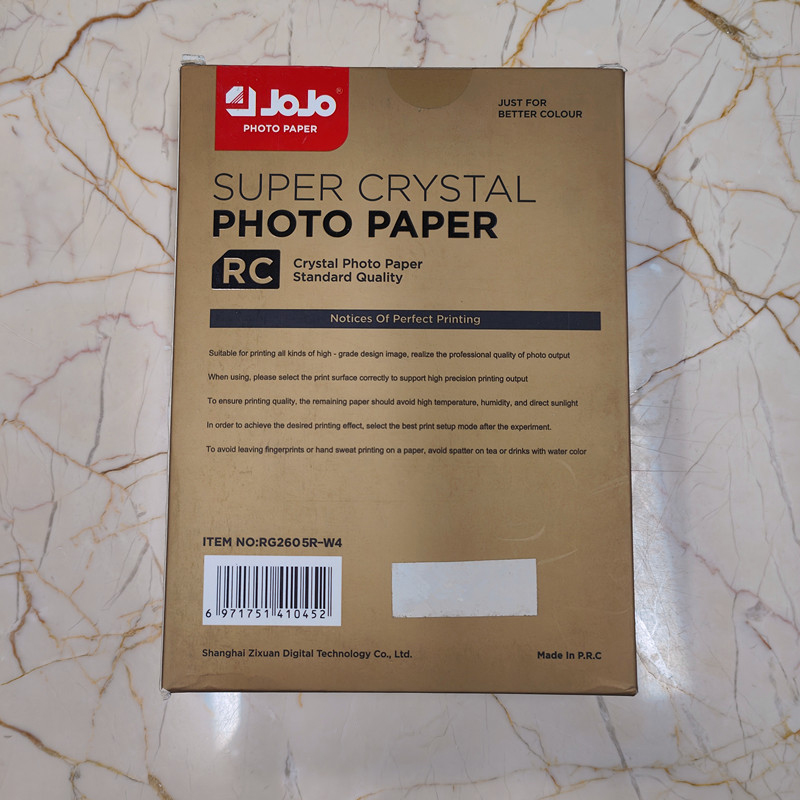

In the world of digital printing, achieving accurate and consistent color reproduction is a critical factor that influences the overall quality of the final output. One key element that plays a significant role in determining color accuracy is the composition of the ink used in printing. Whether printing on JoJo inkjet photo paper, transparent thermal paper, or thermal transfer paper roll, understanding how ink formulation interacts with different substrates is essential for professionals aiming to produce vivid and reliable prints.

Understanding Ink Composition

Ink used in printing generally consists of pigments or dyes suspended in a carrier fluid, along with various additives that influence drying time, adhesion, and color stability. The two primary types of ink colorants are pigment-based and dye-based inks.

Pigment-based inks contain solid particles that sit on the surface of the paper or film, offering good resistance to fading and water. Dye-based inks, in contrast, dissolve completely in the carrier fluid, allowing for deeper penetration into the printing substrate. Each type of ink composition behaves differently when printed on various materials, such as JoJo inkjet photo paper or transparent thermal paper.

Interaction Between Ink and Printing Media

The choice of printing media directly affects how ink behaves and, consequently, impacts color accuracy. Jojo inkjet photo paper, designed specifically for inkjet printing, features coatings that optimize ink absorption and color reproduction. The coatings control how quickly the ink dries and how much it spreads on the surface, helping to preserve the sharpness and vibrancy of colors.

In contrast, transparent thermal paper is often used for printing images or texts that require see-through properties, such as labels or overlays. Since this paper has a different surface texture and coating compared to photo paper, the ink formulation must be adapted to ensure proper adhesion and prevent smudging. The thermal coating layer on this paper also affects how pigments or dyes fix to the surface, influencing the final color output.

Thermal transfer paper roll, frequently used in applications like garment decoration or product labeling, works with heat-activated inks or ribbons rather than traditional liquid inks. The composition of inks or dyes in thermal transfer ribbons must be compatible with the thermal paper to ensure clean transfers with accurate color reproduction. This process involves melting the ink onto the paper surface, and the ink’s chemical properties impact how well colors are transferred and how stable they remain after application.

Pigment vs. Dye-Based Inks and Their Impact on Color Accuracy

Pigment inks tend to produce more durable prints with better resistance to water and light exposure. When used on jojo inkjet photo paper, pigment inks generally maintain color fidelity over time, although they might have a narrower color gamut compared to dye-based inks. This means some bright or saturated colors might not appear as vivid, but the colors printed tend to be stable and consistent.

Dye-based inks typically offer a wider color gamut and can deliver more vibrant hues, especially on glossy or semi-glossy surfaces like many inkjet photo papers. However, their tendency to soak deeper into the paper fibers can sometimes cause slight color bleeding or reduced sharpness if the paper’s coating is not optimized. On transparent thermal paper or thermal transfer paper roll, dye inks may pose challenges due to their solubility and potential for migration, which can affect print clarity and color precision.

Additives and Ink Formulation

Beyond pigments and dyes, additives in ink formulation play a crucial role in achieving color accuracy. Surfactants improve ink flow and wetting on different surfaces, while humectants help control drying times to avoid clogging in printheads. The balance of these components must be carefully adjusted to suit specific substrates such as jojo inkjet photo paper, ensuring that the ink spreads evenly and fixes properly.

In thermal transfer applications, the ink or dye composition in ribbons includes waxes, resins, and polymers designed to melt and bond with thermal transfer paper roll surfaces. These ingredients influence the sharpness of the printed image, color density, and resistance to wear. Compatibility between the ink composition and the thermal paper is essential to prevent issues like smudging, fading, or incomplete transfers.

Practical Considerations for Achieving Accurate Colors

To maximize color accuracy in printing, it is important to select inks formulated specifically for the intended printing media. Using jojo inkjet photo paper with inks designed for inkjet printing generally yields more predictable results than using generic inks. Similarly, transparent thermal paper requires inks or ribbons compatible with its coating and thermal properties.

Calibration and profiling also contribute to managing color accuracy. ICC profiles that account for the specific ink composition and substrate can help printers reproduce consistent colors across different devices and print runs. Regular testing and adjustments may be necessary, especially when working with diverse materials like thermal transfer paper roll and photo paper in the same workflow.

Ink composition has a direct and meaningful impact on color accuracy across various printing materials, including jojo inkjet photo paper, transparent thermal paper, and thermal transfer paper roll. The interaction between pigments or dyes, additives, and substrate coatings determines how colors appear, their sharpness, and their durability. Careful consideration of these factors, combined with appropriate printing technology and calibration, supports the production of prints that meet the desired visual standards in digital printing applications.

English

English Español

Español 中文简体

中文简体 Português

Português